New flexible material to overcome FKM and SS, Venair drives PEMFC hoses industry

Hose manufacturing for Fuel Cell industry, and specifically in PEM Fuel Cells, uses common materials widely used in other industries like combustion engines in automotive sector such as silicone or FKM. These materials have found a place in the Fuel Cell sector as a provisional solution even though it´s known they are not the best ones given the demanding requirements of this sector and systems specially in terms of material purity.

PEM Fuel Cells are meant to play a very important role in the future of energy. Given the high sensitivity of the system It is vitally important to consider some demanding requirements that are critical and cannot be ignored when designing and choosing the right materials for all the components in the system.

By a careful analysis of those critical specifications, Venair Group has developed the first material specifically formulated to meet the main requirements of the PEM Fuel Cell sector.

VENA® PEM CELL is the result of more than 5 years of work during which Venair's R&D department has been researching the subject to develop the right material for hose manufacturing that can fit any part of the PEMFC system. (Anode, Cathode, DI Water and Cooling systems).

The new material can be molded into all kinds of shapes, with different colours or connections fitting all the demands of our customers. Most importantly, it meets the 4 critical requirements of the PEMFC hoses industry:

- Low permeability

- High purity

- Cleanliness

- Low conductivity in contact fluids

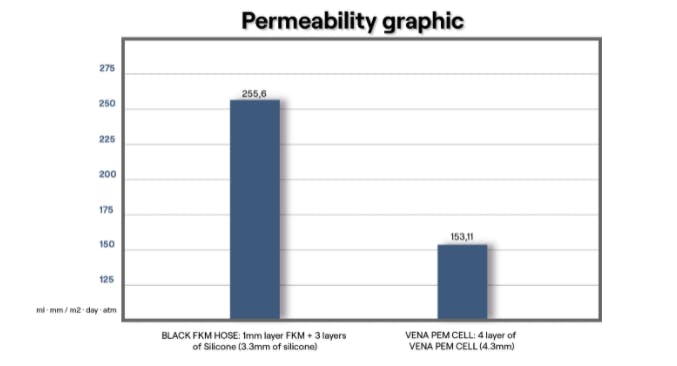

Low Permeability: VENA® PEM CELL has been specifically formulated to have around two times less permeability than standard FKM/Silicone construction. Low permeability is critical at the anode side where there is H2 flow. By using VENA® PEM CELL we can avoid serious H2 leaking through hose walls and contribute in this way to increase the security of the whole system.

High Purity: VENA® PEM CELL has been designed to avoid as much as possible the release of critical contaminants to the PEM membrane. There are certain critical contaminants that damage the membrane very significantly and reduce the efficiency of the system. This is why it is key to focus on these contaminants and reduce them to a minimum High purity has been one of the main concerns for the development of the VENA® PEM CELL .

Cleanliness: All hoses from Venair´s PEM Fuel Cells catalogue are specially treated before, during and after production. In this way, production, cleaning, and packaging processes have been specifically created to meet the high requirements of the industry in terms of cleanliness and quality.

Low Conductivity in contact fluids: The change in medium conductivity is another critical factor in these systems. VENA® PEM CELL hoses have been developed to impart almost no conductivity to contact fluids.

Improvement in features, but also improvement in the market

The entire formulation of the VENA® PEM CELL material has been focused on improving the permeability of the FKM containing constructions and reducing the kind of critical contaminants in the Polymer Electrolyte Membrane that can influence in acidification of the medium inside the hose and increasing its conductivity.

"VENA® PEM CELL hoses show us the difference between reusing materials from other industries, or creating a specific material for PEMFC systems," explains Marc Balcells, Fuel Cells Project Manager at Venair Group.

The new material for PEM system hoses also has certain advantages over FKM from a commercial point of view. FKM is the material that has been most widely used in PEMFC tubes, especially in the Anode and Cathode.

However, FKM presents some very important problems at the market level:

- Scarcity worldwide

- Uncertain supply chain

- Very high price

- Difficulty producing very complex parts (as required in the industry)

That is why Venair Group has focused on finding a solution that would overcome the current characteristics of FKM construction and dodge the current FKM market situation.

If you want to know more about the new VENA® PEM CELL material, you can contact Venair’s Fuel Cells team. We have at your disposal many tests and analyses that show the characteristics of our product in comparison with other products on the market.