FAQs

Yes, it is possible to manufacture custom sleeves or kits with the requested measure, but the process of developing a new piece involves the use of high-tech tools and tooling manufacture, whose cost must be indicated by the applicant.

Therefore, we recommend using this service only for series production.

In case you need a single kit or piece, it is recommended to make a custom assembly using the universal pieces available on our website: elbows, sleeves, reductions, etc.

Universal parts

If there is a possibility to choose the piece in other colors, you will find it in the description with the options available on the product page.

Kits

All kits are available in 4 standard colors: blue, red, yellow and black.

It is possible to manufacture other colors for the products and the marking, whenever it is on request. The available colors are indicated in the characteristics of each kit.

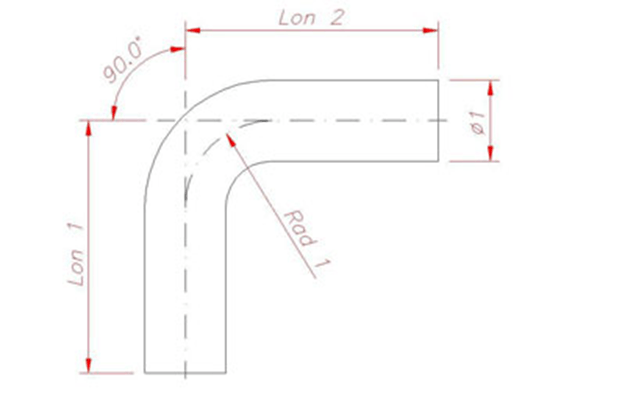

The length of an elbow is measured from one end of the elbow to the center of the circumference of the other end.

In the lower image you can see an example:

When choosing a flexible hose for a certain application the following points must be considered:

Pressure – Vacuum

Operational pressure and vacuum values. Water hammer.

Conveyed products

Nature, designation, concentration, working temperature. Form: liquid, gas, or solid. In the case of the latter: granulated, density, behavior of transported solid product, nature, speed of travel and flow of transported fluid. Frequency of use.

Environment

Place of use, ambient temperature, hygrometric grade, exposure or lack of exposure to atmospheric agents and ozone. Products that may be in contact with the end of the flexible hose.

Mechanical limitations

Minimum bending radius in service. Limitations in terms of traction, torsion, flexion, vibration or compression. Risk of impact, abrasion and corrosion. Work position: on the floor, suspended or submerged.

Connection used or expected to be used

Connection: type, dimension and class of thread. Hose: outer and inner diameters. Adjustment length.

Particular conditions

In relation to this matter, it is in the user’s interest to choose flexible hoses that conform to the standards in force in the country of use, provided that these exist within the field of application in question.

In cases of difficulties regarding interpretation or where the necessary information does not appear in the available documentation, the user of the flexible hose is advised to consult the manufacturer.

In order to achieve the proper functioning of the parts it is very important that, during assembly and use, the sleeves are not stained with aggressive products such as a battery, etc. braking or servo-steering fluid or others. If the silicone parts are in continuous contact with some of these elements, they could be damaged immediately.

The hoses can withstand small oil spots provided regular maintenance is carried out, cleaning the parts with hot soapy water and always avoiding the use of aggressive agents, as they deteriorate the appearance and natural shine of the silicone.

Storage life should be reduced as much as possible. Therefore, stock rotation should be ensured, applying the rule “first in, first out”. When long term storage cannot be avoided, e.g. for one year, the item should be thoroughly checked before it is put into operation.

Storage temperature should be kept at between 0°C (32ºF) and 35°C (95ºF) wherever possible (optimum temperature 15°C/59ºF). Relative humidity should preferably not exceed 65%.

Flexible hoses should be stored without excessive restriction, lengthening or deformation. All contact with sharp or angular objects or materials must be avoided. Hoses must be stored in a dry place in storage boxes whenever possible. Flexible hoses that are coiled up should be stored flat and preferably not stacked. In cases where this is impossible, the height of stacks should be limited so that the items at the bottom of the stack are not deformed. Heavier items should be placed at the bottom and lighter items should be placed at the top. The coil must be at least equal to the minimum curvature radius specified by the product manufacturer or standards. Hanging coiled hoses from spikes or hooks is not recommended. Flexible hoses that are supplied in lengths should be stored flat without folds.