How to connect and design a flexible hose for load cells tanks?

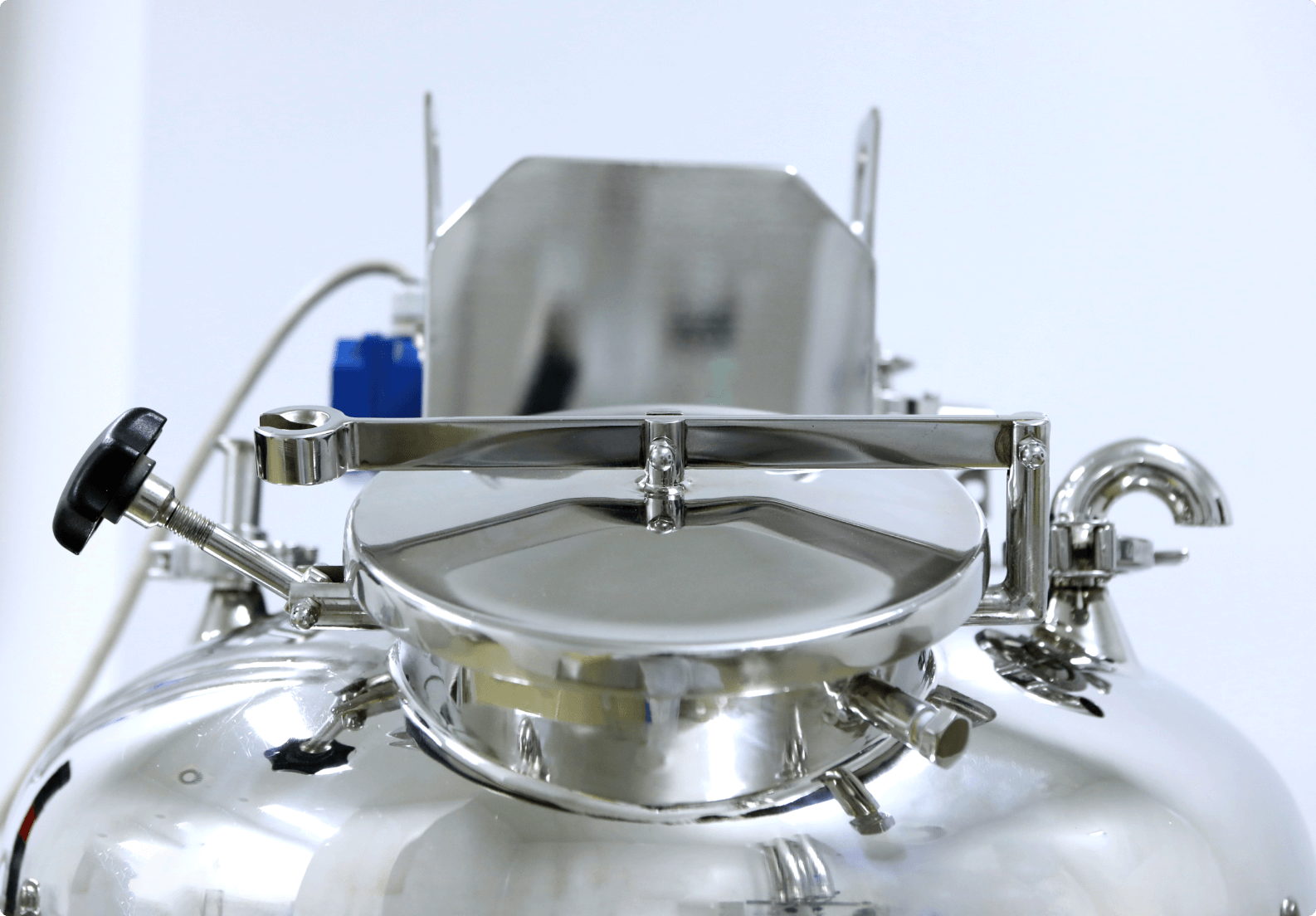

When designing and installing flexible hoses on load cells tanks there are some essential rules that need to be followed to guarantee longevity of the hoses and reducing errors on the measuring accuracy of the weighing device. Tanks usually require highly flexible connections for supply and discharge or for the supply of additional units mounted on the tank.

The best way to avoid weighing issues and breakdowns is to choose an appropriate hose with an optimal design as to not exert unwanted forces when the tank is full. Here is a guideline to consider for flexible connections during the design and planning phase of the tank:

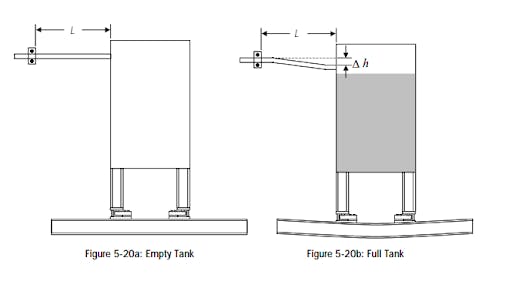

1. Use lighter hoses with the smallest possible diameter to guarantee the most flexibility

On the above drawing, you can see two tanks mounted on weighing modules. When comparing the two tanks, one is empty and the other one is full. When the tank is empty, the hose remains in a horizonal orientation and does not exert any force on the tank. However, when the tank is full the hose moves downwards because of the load inside the tank thus pulling the hose downwards by the same distance as the tank deflects. The hose exerts an upward force on the tank that affects nd alters the weight measurements. This issue can be solved by using a more flexible hose that will exert les force on the tank.

Our Vena Sil 650V is usually recommended for these applications as the design ensures a balance between strength, lightness and flexibility that makes it easy to handle. The Vena Sil 650V is also highly resistant to pressure, temperature and constant movement and offer a very short bending radius.

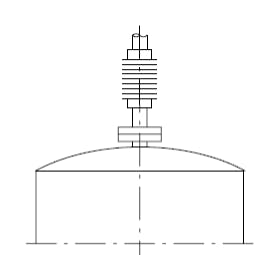

2. Use vertical positioned connections when possible

Another possible solution is using elastic silicone connections to prevent force shunts, compensators, or even elastic couplings. In these applications, the compatibility of the material with the filling and the cleaning materials is important, especially in the food and pharmaceutical industry.

Our range of Pharmaloaders, elastic compensators are solutions that we can recommend for weighing tank outlets as it can help compensate vibrations and level differences. They are custom made and can be reinforced with clamps and fabric, or be produced with conductive materials or FKM layers.

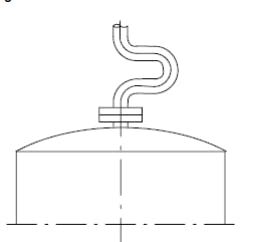

3. If you use semi-rigid flexible hoses, run the hoses horizontally from the tank.

If you run hoses that are not flexible in a vertical direction, the hose becomes more yielding as length increases, and the mechanical force exerted by the hose on the load cells decreases and it is no longer useful for measuring accuracy.

For these applications, we recommend Vena Sil 640, it is convenient for straight sections, and it is equipped with metal fittings connections. It can be used for particles metal detectors in sensitive processes.

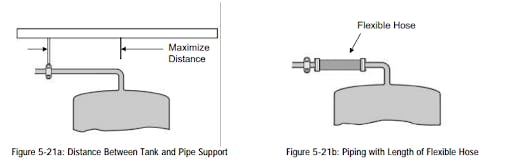

4. Include the first rigid support of the hose as far away from the tank as possible.

Installation is important to avoid deflection problems. It is convenient to leave a larger distance between the tank and the hose support. However, it is preferable to use a flexible hose so that the hose does not exert unwanted forces when the tank deflects.

Conclusions

Flexible connections decisions regarding design and installation are critical to avoid wighning issues and breakdowns. If you need engineering advice or a special design for your machinery, don’t hesitate to get in contact with our network of international advisors and engineers. They’ll provide you the most optimal solution to avoid this major issues.