Vena Abrasil® provides solution for a major pizza manufacturer

Sector and customer

- Food production

- Local Spanish manufacturer of pizza.

Context

A renowned Spanish manufacturer of pizzas needed flexible resistant hoses that could resist the higher propulsion and the abrasion of its dispensing cheese lines.

The company used hoses that couldn’t resist the abrasion of the higher impulsion of the cheese and needed to replace the hoses on a regular basis , leading to serious operating and cost problems.

Challenges faced

The company used hoses that couldn’t resist the abrasion of the higher impulsion of the cheese and needed to replace the hoses on a regular basis, leading to serious operating and cost problems.

For this reason, when one of our sales engineers presented one of our latest innovations, Vena® Abrasil, a flexible hose able to resist abrasion and CIP processes, it seemed like the perfect solution for the problem.

However, the company needed to present a solution that also allowed them to adapt to their exhaustive quality controls.

Operating conditions

- Temperature

- Pressure

- Machine

- Bending radius required

Solutions implemented

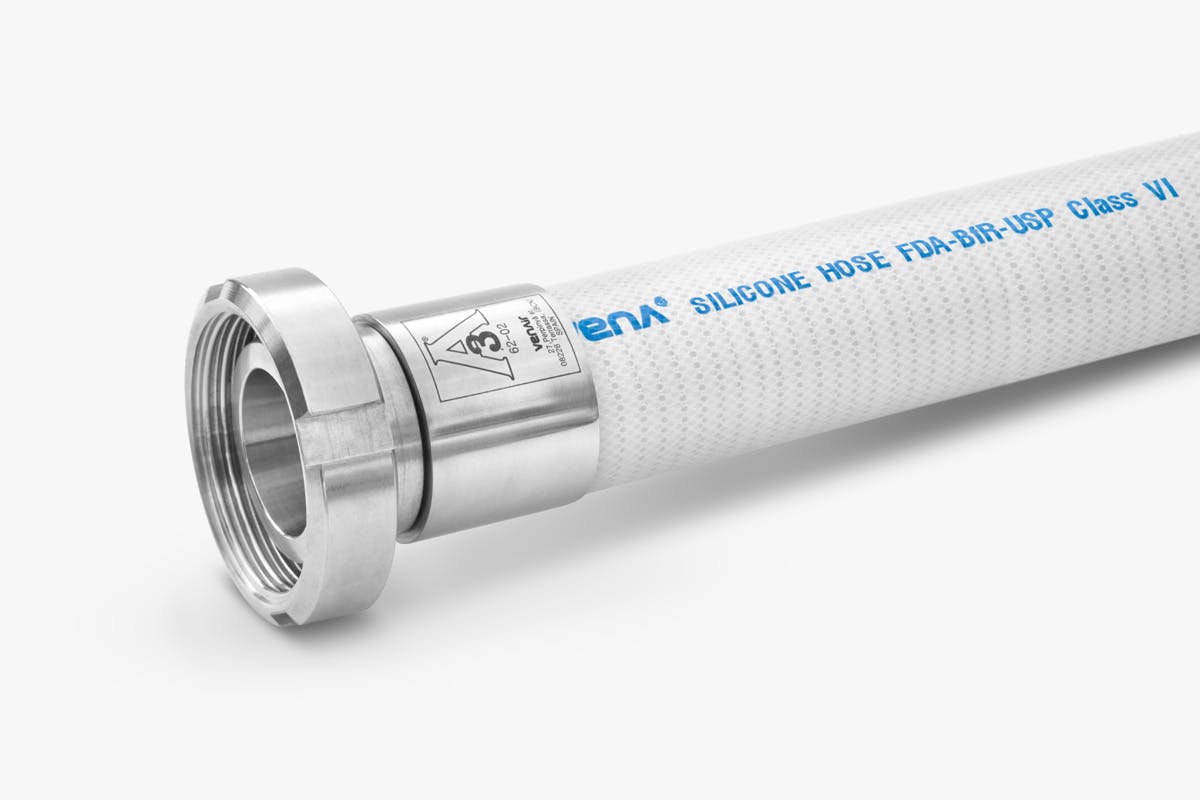

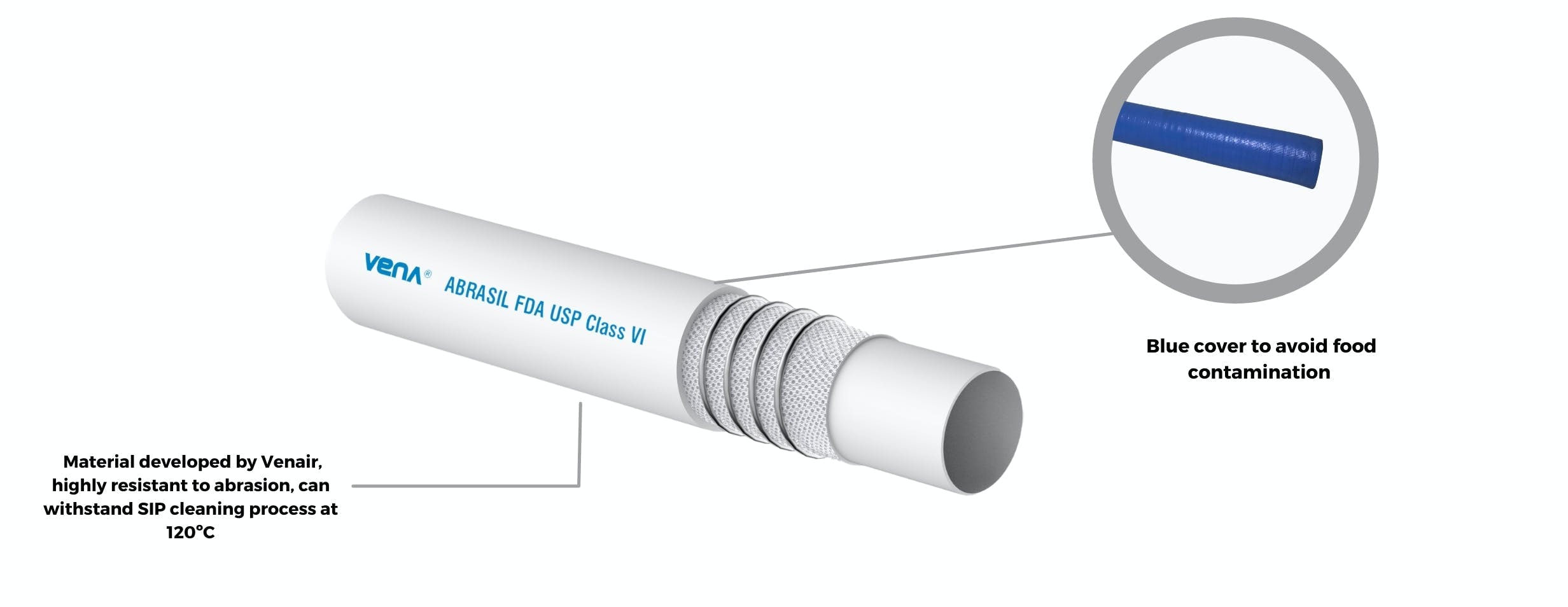

Venair engineers recommended that the customer switch to Vena® Abrasil due to its highest resistance to abrasion and resistance to constant movement. Also, for dispensing the product, flexibility was needed, so any other product made with other materials like polyurethane wasn’t suitable.

Additionally, Venair engineers provided the pizza manufacturer with a customization in the cover material of Vena® Abrasil, they added a blue cover that allowed the manufacturer to improve its quality control procedures, being able to detect any possible detachment in the pizza ingredients.

Benefits and ROI

The renowned manufacturer experienced a notable change since the installation, the hoses have maximized their useful life and the impact on the reduction of costs is considerable.

The company maintains a good partnership with Venair and we’re working together on future projects.

Conclusions

Investing in high quality hoses that adapt perfectly to your fluid and machinery needs is crucial for maximizing hose life and optimizing operability.